- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Storage Tanks

- Industrial Conveyor

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Biomass Fired Hot Air Furnace

- Coal Fired Hot Air Generator Furnace

- Coal Burning Hot Air Generator

- Pellet Hot Air Furnace

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Butterfly Valves

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

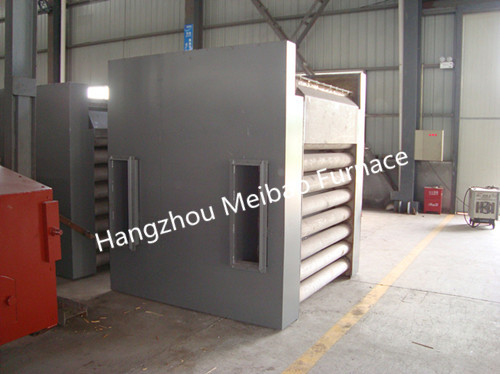

Flash Dryer

Product Details:

- Power 7.5 kW to 30 kW

- Condition New

- Product Type Industrial Drying Equipment

- General Use Powder Drying, Chemicals, Pharmaceuticals, Food Industries

- Material Stainless Steel

- Capacity 50 to 2000 kg/hr

- Weight (kg) Approx 1200 kg

- Click to view more

X

Flash Dryer Price And Quantity

- 1 Set

- Overload protection, Emergency stop, Earthing

- Food, Chemical, Pharmaceutical, Mineral and Agricultural products

- Steam, Gas, Electric, or Oil

- Up to 30 m/s

- Ambient to 250C

- 75 dB

- Up to 1500 kg/h

- Digital with safety interlocks

- Floor-mounted

- Automatic or Manual

Flash Dryer Product Specifications

- Stainless Steel

- No

- Approx 1200 kg

- Three Phase Electric Motor

- Powder Drying, Chemicals, Pharmaceuticals, Food Industries

- Direct / Belt Drive

- High efficiency, Uniform drying, Continuous operation, Easy maintenance

- Customized as per requirement

- 50 to 2000 kg/hr

- 7.5 kW to 30 kW

- New

- Industrial Drying Equipment

- Heavy Duty Stainless Steel Shaft

- Optional

- 415 V

- Silver Metallic

- Flash Dryer Unit

- Yes

- Overload protection, Emergency stop, Earthing

- Food, Chemical, Pharmaceutical, Mineral and Agricultural products

- Steam, Gas, Electric, or Oil

- Up to 30 m/s

- Ambient to 250C

- 75 dB

- Up to 1500 kg/h

- Digital with safety interlocks

- Floor-mounted

- Automatic or Manual

Flash Dryer Trade Information

- 10 Set Per Month

- 30-90 Days

Product Description

The drying equipment based on the advanced technology of absorbing foreign similar products. It is a new type of drying equipment developed by our company to dry paste, filter cake and heat sensitive materials. The hot air enters the agitating and pulverizing drying chamber from the bottom of the dryer at an appropriate spraying speed by the inlet pipe, and the material is strongly sheared, collided and rubbed to be micronized, thereby enhancing mass transfer and heat transfer.

Applicable materials:

1. Ceramics: kaolin, silica, clay, etc.

2. Food: soy protein, starch, distiller's grains, wheat sugar, wheat starch, etc.

3. Dyes: anthraquinone, iron oxide, pigment, butyric acid, various dye intermediates.

4. Organics: atrazine (pesticide), benzoic acid, carboxybenzene, sodium oxalate, acetate, etc.

5. Inorganic class: calcium carbonate, copper sulfate, iron oxide, barium carbonate, antimony trioxide, various metal hydroxide, etc

Efficient and Versatile Drying Technology

The Flash Dryer offers fast, uniform drying tailored for powders in food, chemical, pharmaceutical, mineral, and agricultural industries. Its advanced design supports various heating sources and provides a moisture evaporation capacity up to 1500 kg/h, enabling productivity without compromising on quality.

User-Friendly Operation and Safety

A digital control panel with safety interlocks ensures easy monitoring and reliable operation. Built-in overload protection, emergency stop, and earthing features contribute to a safer working environment, while its automatic or manual discharge provides flexibility to suit specific processing requirements.

Tailored for Industrial Needs

With customizable dimensions, heavy-duty stainless steel construction, and the capability for PLC control, this Flash Dryer is seamlessly integrated into diverse production lines. Its continuous operation, low maintenance requirements, and high efficiency guarantee long-term performance for manufacturers, distributors, and service providers.

FAQs of Flash Dryer:

Q: How does the Flash Dryer ensure uniform and efficient drying of powders?

A: The Flash Dryer employs a high-velocity inlet air system (up to 30 m/s) and a temperature range of ambient to 250C, ensuring rapid moisture evaporation and uniform drying across the entire material batch. Its heavy-duty stainless steel construction and continuous operation further contribute to consistent performance.Q: What types of materials and industries can use this Flash Dryer?

A: This Flash Dryer is suitable for drying powders in food, chemical, pharmaceutical, mineral, and agricultural industries. Its versatility makes it ideal for manufacturers, exporters, and service providers needing to process a diverse range of products efficiently.Q: When should I opt for automatic versus manual discharge in the drying process?

A: Automatic discharge is recommended for continuous, large-scale operations to improve efficiency and minimize labor, while manual discharge may be preferred for smaller batches, product changes, or when precise control over material handling is required.Q: Where is the Flash Dryer typically installed within an industrial facility?

A: The Flash Dryer is designed as a floor-mounted unit with customized dimensions to fit seamlessly within production lines. It is often positioned close to material feed and packaging stations for streamlined workflow in processing plants.Q: What safety features are included with the Flash Dryer?

A: Safety features include overload protection, emergency stop, and earthing. The digital control panel with safety interlocks monitors critical parameters, minimizing risks during operation and ensuring safe shutdowns in the event of errors or electrical issues.Q: How easy is it to operate and maintain the Flash Dryer?

A: Operation is simple thanks to the digital control panel, while the stainless steel construction and direct/belt drive systems require minimal maintenance. The optional PLC control allows further automation, making monitoring and adjustments straightforward.Q: What benefits do buyers in China get from choosing this Flash Dryer?

A: Buyers benefit from high efficiency, uniform drying, and robust safety features. The machines reliability, low noise ( 75 dB), flexible heating options, and easy customization make it ideal for a wide range of industrial applications with excellent long-term value.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email