- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Storage Tanks

- Industrial Conveyor

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Biomass Fired Hot Air Furnace

- Coal Fired Hot Air Generator Furnace

- Coal Burning Hot Air Generator

- Pellet Hot Air Furnace

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Butterfly Valves

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

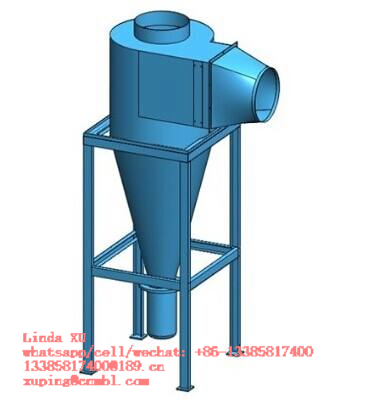

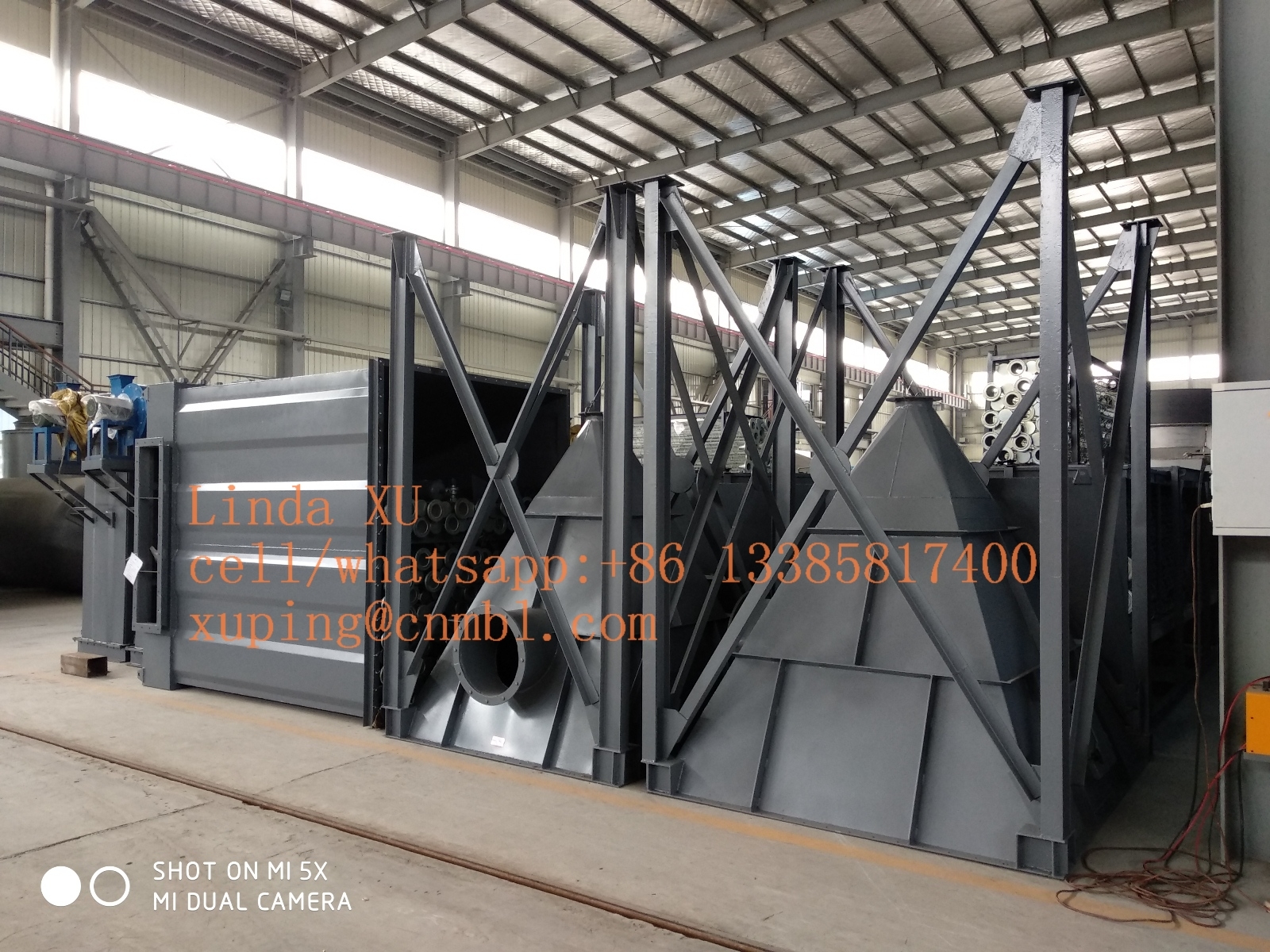

Cyclone Separator Dust Collector

100000-500000 USD ($)/Set

Product Details:

- Product Type Cyclone Separator Dust Collector

- General Use Chemical industry

- Material Stainless Steel

- Click to view more

X

Cyclone Separator Dust Collector Price And Quantity

- 1 Set

- 100000-500000 USD ($)/Set

Cyclone Separator Dust Collector Product Specifications

- Stainless Steel

- Chemical industry

- Cyclone Separator Dust Collector

Cyclone Separator Dust Collector Trade Information

- 100 Set Per Day

- 30-90 Days

Product Description

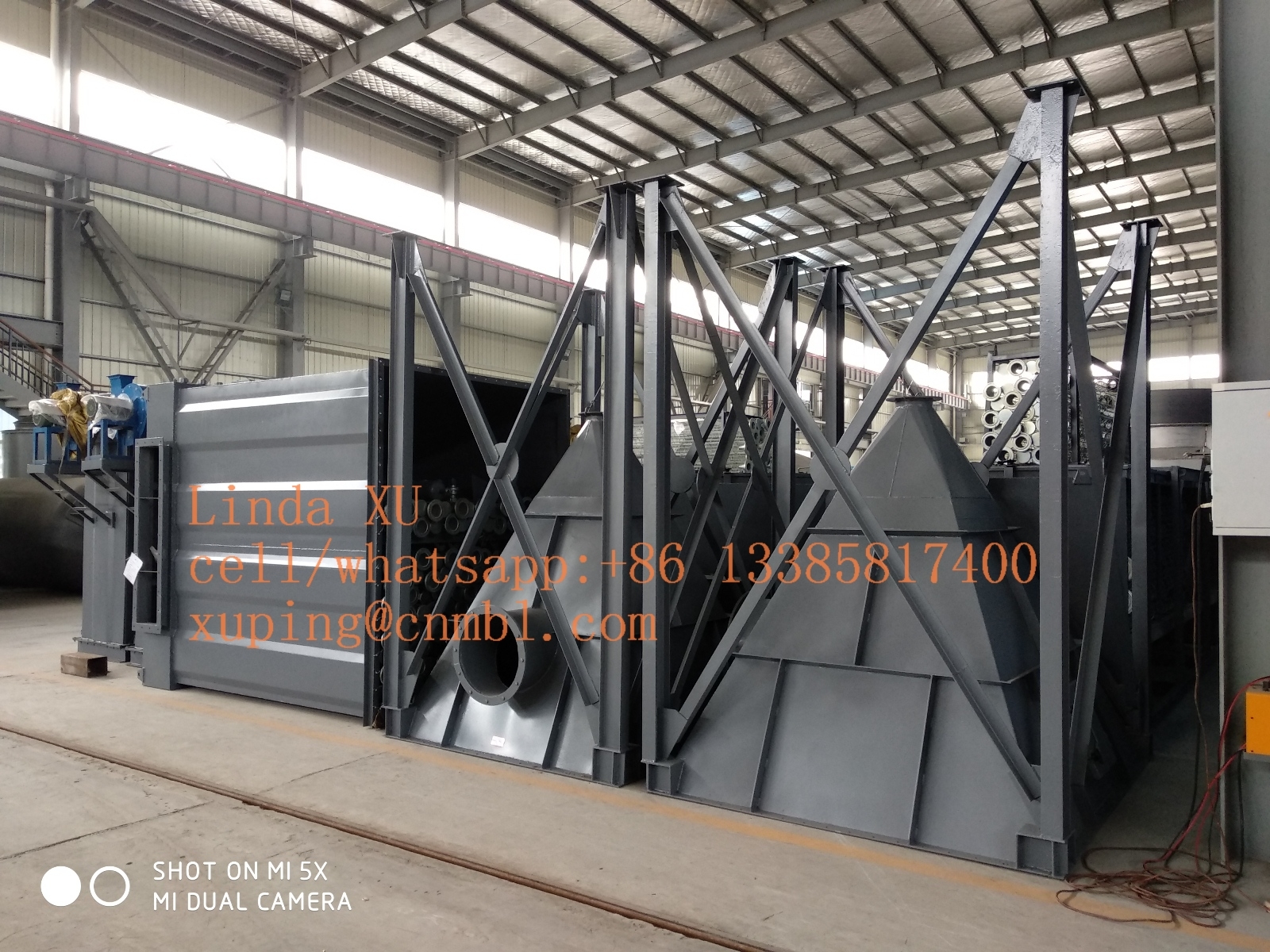

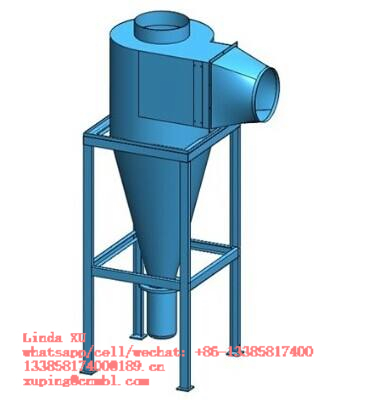

Following transparent business policies, we have gained immense appreciation in market by providing a wide assortment of Cyclone Separator Dust Collector to the clients within stipulated time frame. It is manufactured using quality assured components under the strict surveillance of adept professionals with the aid of cutting-edge techniques. It provides extensive aid in trouble free separation of dust particles and contamination from fluids. Moreover, this Cyclone Separator Dust Collector can be purchased from us at affordable rates.

Advantages:

- High Efficiency

- Durable quality

- Stable pressure drop

- High temperature capability

- Low Maintenance

- Compact design

- No moving parts within the conveying system

- Low operation and maintenance cost compared to screw conveyors.

Industries Catered:

- Plastic / Polymer Industries

- Cement Industry

- Paper Mills

- Textile Industries

- Agro Industries

- Wood working industries

- Tobacco Processing Industries

- Food Processing Industries Grain Handling

- Powder Coating Industries

- Plastic / Polymer Printing and Processing Industries

- Paint Booths

- Paint processing Industries

Further Details:

Cyclone separators are a kind of air pollution control device. They are known as pre-cleaners, and mostly used to roughly remove larger particulate matter pieces. They are effective in removing large and high-volume dust for many industrial applications. These devices are perfect for high temperature, high dust load, and product recovery applications. Also, they offer an economical solution to a range of dust collection jobs.

Operational Explanation

Through air inlet dust-laden air enters the unit, and it is diverted by way of helical baffle. The heavy dust is moved by centrifugal force to the interior walls, and it moves them to the base of the unit. The inner cylinder carries clean air, and discharges to atmosphere, or after-filters.

Benefits of cyclone dust collector:

- Low capital cost.

- Quality to work at high temperatures.

- Handle dry materials and liquid mists.

- Maximum airflow, and very cost efficient.

- Heavy-duty construction for longer life.

- Small footprint - needs comparatively small space.

- Low in cost, effectively collect most particles, require little maintenance.

- Can be utilized alone, as a pre-cleaner, or with bag filter assembly.

Details

- Size: The diagram of this equipment has been made as per customers' requirements and location and state of the site.

- Transportation: container

- Application: efficiency in isolating powder or dust from air.

- Type: MBK

Working principle: Gas full with dust particles infiltrate into cylinder by passing through a rectangular shaped inlet pipe. The centrifugal force active inside the inlet pipe is instrumental in throwing dirt to its wall. The thrown dust moves downward in spiral direction due to the agitation caused by air flow. During elimination of dust particles, its reflective screen creates reflection effect due to which most part of the air moves towards exhaust pipe for evacuation purpose. The remaining air permeates into ash hopper with the help of ring gap created between the dust cone and reflective screen. Dust is accumulated in the gas hopper and the air passes to the exhaust pipe through the air holes situated in the reflective screen. A single MBK can remove 4000-40000m3 gas per hour.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email