- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Storage Tanks

- Industrial Conveyor

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Biomass Fired Hot Air Furnace

- Coal Fired Hot Air Generator Furnace

- Coal Burning Hot Air Generator

- Pellet Hot Air Furnace

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Butterfly Valves

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

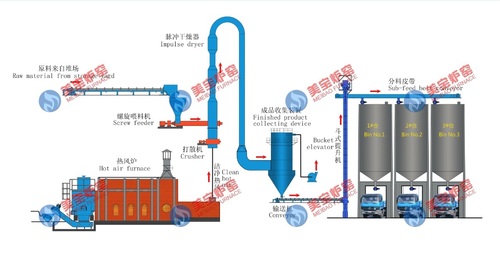

Gypsum Drying Production Line

100000-500000 USD ($)/Set

Product Details:

- Product Type Gypsum Drying Production Line

- General Use Chemical industry

- Material Stainless Steel

- Click to view more

X

Gypsum Drying Production Line Price And Quantity

- 1 Set

- 100000-500000 USD ($)/Set

Gypsum Drying Production Line Product Specifications

- Stainless Steel

- Chemical industry

- Gypsum Drying Production Line

Gypsum Drying Production Line Trade Information

- 100 Set Per Day

- 30-90 Days

- Contact us for information regarding our sample policy

- All India

Product Description

Our advanced production setup enables us to offer the finest quality Gypsum Drying Production Line. This line is extensively admired for its smooth operation and is demanded in ceramic, fertilizer and other industry. The provided line is manufactured under the supervision of our adept professionals by utilizing top grade components and cutting-edge technology. The offered Gypsum Drying Production Line is available with us in diversified technical specifications as per the application needs of patrons at economical prices.

Features:

- Low maintenance

- Excellent operational fluency

- Rigid construction

- High performance

Gypsum Drying Technology

We can plan the gypsum manufacturing line with turnkey arrangement from a to z:

- Use drive dryer, with high productivity and limit while less power utilization

- Product with great quality and stable

- Minimum investment with less operation price

Further Details:

Gypsum Drying production line usages:

- It is extensively taken into use in the domain of metallurgies, building materials, cement, chemical industry and so on.

- It can dry coal powder, slag, mining powder, sand, limestone, clay, solid dryer, manure, slurry, manganese ore, palm fiber, and so on. It is manufactured into lifting blade, rotary body, supporting device, driving device, etc.

- The dryer has benefits of high efficiency, reasonable structure, less energy consumption and suitable for transportation.

- We deliver the following dryer: sand dryer, sawdust dryer, wet material rotary dryer, coal slime dryer, coal dryer, ore concentrate dryer, bentonite dryer, cassava dryer, gypsum dryer, wood chip dryer, and cow dung dryer.

Functioning belief of gypsum drying production line:

- The raw material go into lignite drying machine through conveyor at the beginning of the dryer have furnace, it will offer the temperature for the dryer and the termination of the dryer have fan, this fan captivates the heat going into the dryer, in the the lignite dryer have negative compression, so the heat must go into this lignite drying machine.

- There is a lifting plate, it will elevate the basic material, therefore the raw material and heat will be completely contact in interior of the lignite drying machine.

- The dried substance will move out of the release machine.

- The cyclone gather the dust from this lignite drying machine.

The FGD gypsum drying production line characteristics:

- The core espouses assembled structure that has enhanced the exactness of the apparatus and it is convenient to transference and install.

- As per the features of dissimilar fertilizers, we have set the second granulation region judiciously so as to advance the granulation outcome.

- Adopts collected winch board so as to exchange warmth fully and lesser the energy consumption.

- Temperature introduction monitor, airproof setting and uniform vibration, that expand act and output efficiently.

- The varied combustion furnace is a kind of energy effectual and has the features of convenient regulation, smaller area, and armed with greenhouse

Benefits of gypsum drying production line:

- The drum dryer utilize telescope-feed construction, dry the material rapidly.

- Self-insulation, simple design, advance the heat efficacy to surpass 80%.

- Structure subtle as well as steady operation.

- Decent drying presentation, coal feasting <8kg while drying 1 ton material.

- The fuel can be oil, natural gas, coal, etc. granule, dry mass, and powder substance.

- Decrease land area by 50% associated to single drum rotary dryer, therefore building investment is protected 50% power consumption hoarded 60%.

- Completed product dampness can be accustomed rests on on necessity of client.

- Lower opening temperature, longer sand elimination using life.

- Drive via tug not equipment.

- Completed product temperature lesser than 60 C, packaging can be ended unceasingly.

Fitting of gypsum drying production line:

- The device should be fitted on a level concrete basis with anchor bolts.

- When connecting, you must pay attention to the chief body horizontal and vertical.

- After fitting check all host doors and bolts, if moveable, satisfy fasten them.

- Organize the control switch and power lines as per the equipment power

- After examination, unfilled load examination, if the examination normal, it can be utilized to produce.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email