- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Coal Fired Hot Air Generator Furnace

- Biomass Fired Hot Air Furnace

- Coal Burning Hot Air Generator

- Pellet Hot Air Furnace

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

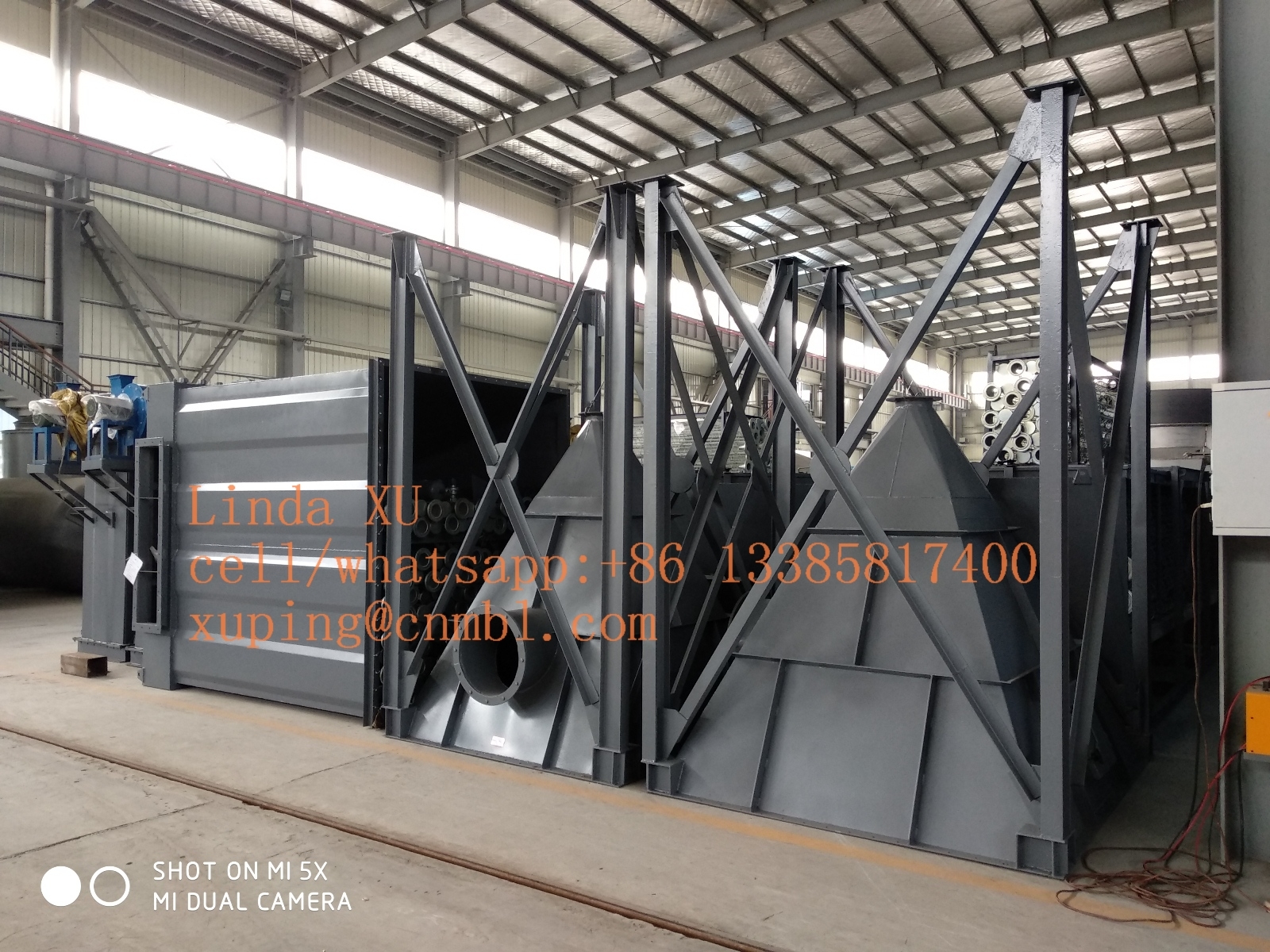

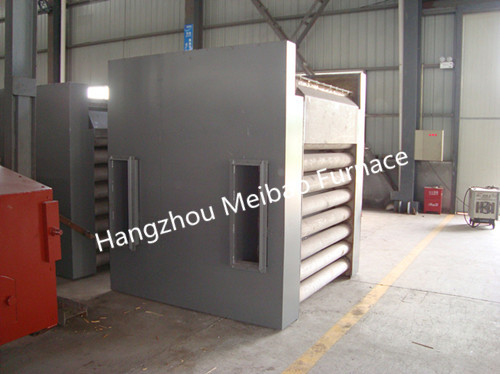

Bag Filter

50000 USD ($)/Set

Product Details:

- Condition New

- Product Type Bag Filter

- Material Stainless Steel

- Click to view more

X

Bag Filter Price And Quantity

- 1 Set

- 50000 USD ($)/Set

Bag Filter Product Specifications

- Stainless Steel

- New

- Bag Filter

Bag Filter Trade Information

- 10 Set Per Month

- 30-90 Days

- Contact us for information regarding our sample policy

- All India

Product Description

To deal with increasing demands, we are manufacturing, exporting and supplying a broad gamut of Bag Filter. This filter is used in chemical plants, food processing and other industry for separating dust from gases. Offered filter is appreciated in the global market for its robust design and leakage proof design. Provided filter is manufactured using quality tested components and pioneering technique at our modern production unit. Clients can purchase this Bag Filter at nominal prices.

Features:

- Longer life

- Heavy duty construction

- Easy maintenance

- High temperature resistance

Further Details:

A bag filter or fabric filter is an air pollution control equipment that effectively removes particulates out of air / gas, released from industrial or commercial processes. It is used in power plants, pharmaceutical processing, steel mills, food manufacturing, chemical, and other industrial establishments.

Main Components of Bag Filter:

- Bag Filter Housing

- Filter Bags

- Bag Cages

- Filter Bag-Venturi Assembly

- Reverse Pulse-jet Cleaning System

- Air Bleeding Arrangement

- Working Principle Of Bag Filter

Dust-laden air enters the lower portion, i.e. the bag filter hopper. The air moves through the filter bag, which holds the dust particles on the surface of the bag. Clean air passes through bags and plenum to the Bag filter outlet. On the outside of the bag filter, the dust is accumulated. There is an increase in differential pressure across filter bags with the collection of dust on the bags. Timekeeper actuated closed pulse valves, pulse the compressed air to open the valves.

There is a flow of high pressure air (4 to 5 bar), from the compressed air header to blow tube. It is throw out from the blow tube by nozzles at a high rate (primary air flow). Air from all nozzles generate secondary airflow. The united effect of primary and secondary air origins an instant pressure rise on clean side of the filter bags. This causes a reverse flow of air through the bags, therefore removing the dust particles clasped on the bags outer surface. By this process, the dust gathered is discharged from the bags and moves into the hopper. It is released by a suitable device from the hopper, i.e. Rotary valve. And the differential pressure is maintained across the Filter Bag.

Features of Dust Collection System

- Effective, and designed according to industrial standards.

- High-quality filter bags for trouble free operation.

- Robust construction and optimal bag spacing.

- Good ratio of pulsing to cleaning time.

- Best air-to-cloth ratio & can velocity, for impressive filtration.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free