- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Storage Tanks

- Industrial Conveyor

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Biomass Fired Hot Air Furnace

- Coal Fired Hot Air Generator Furnace

- Coal Burning Hot Air Generator

- Pellet Hot Air Furnace

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Butterfly Valves

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

Spray Tower Detergent Powder Making Machine

200000.00 - 1000000.00 USD ($)/Set

Product Details:

- Type Powder Detergent Plant

- Capacity Kg/hr

- Detergent Type Cleaner

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Control

- Machine Type Other

- Click to view more

X

Spray Tower Detergent Powder Making Machine Price And Quantity

- 1 Set

- 200000.00 - 1000000.00 USD ($)/Set

Spray Tower Detergent Powder Making Machine Product Specifications

- PLC Control

- 1 year

- Yes

- Other

- Automatic

- Kg/hr

- Cleaner

- Powder Detergent Plant

Spray Tower Detergent Powder Making Machine Trade Information

- 2 Set Per Month

- 90 Days

- Standard packing

- ISO9001

Product Description

Product Description

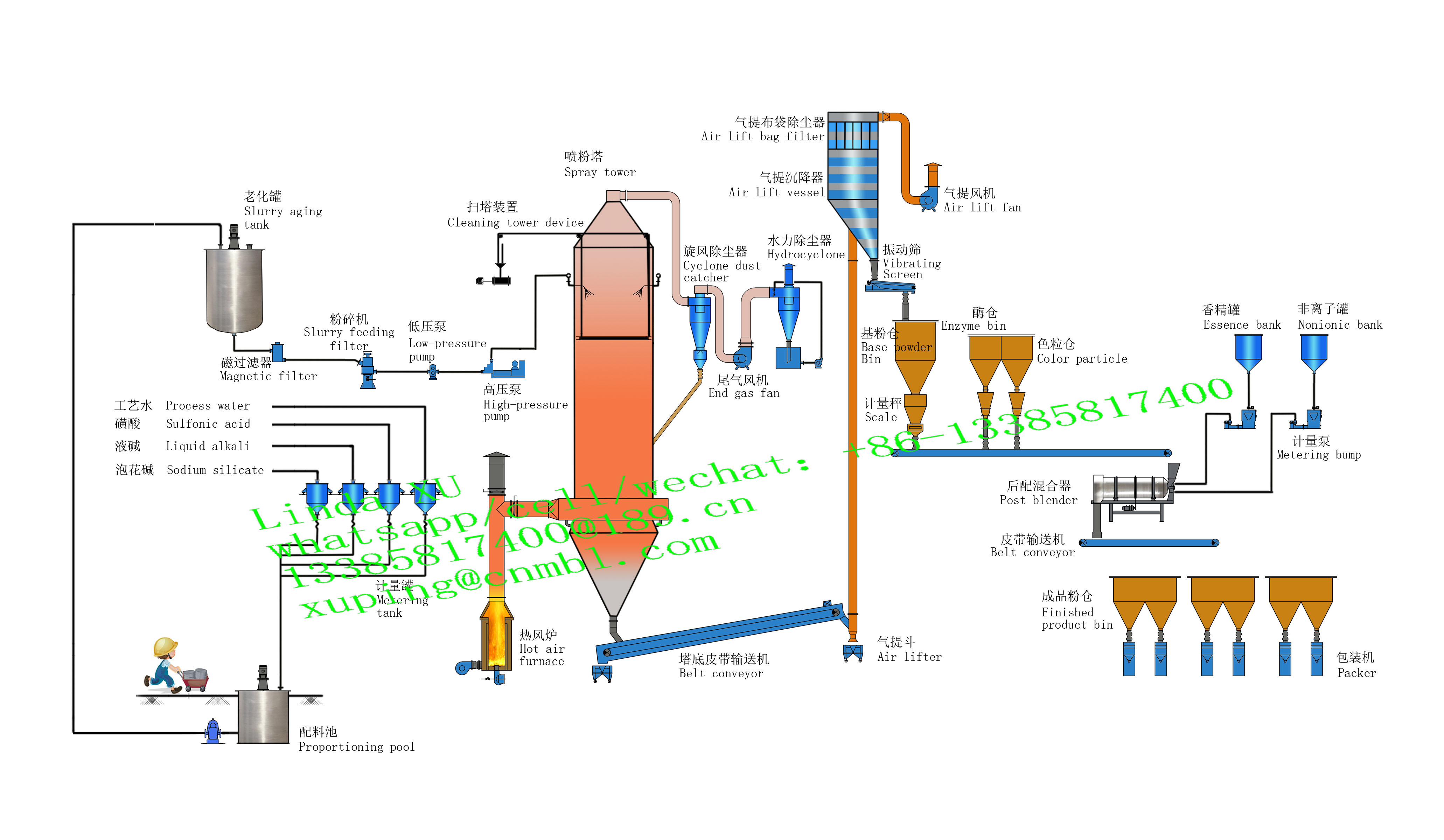

Spray tower detergent powder production system is mainly composed of pre mixing and slurry preparation section, powder drying & shaping system, post blending & packing system, workshop dedusting system, control system,etc

On this process, after weighing powder raw material and liquid raw material based on formula, make slurry in the slurry preparator, then into aging system, after crushing the filtering system, the slurry can be grinding and homogeneous, sent to top of the spray tower by high pressure pump, becoming mist particles under the action of a sprayer, dry and heat transfer with hot air supplied by hot air furnace, become hollow particles in the bottom of tower. After air lifting and aging, make the free water in the surface to form a stable crystal water, get the base powder to make detergent powder.

After sieving the base powder, other materials such as enzyme, color particles, essence, non-ionic etc, can be added into base powder for different requirement, and then put them into post-blending mixer after weighing, after mixing and granulating, the medium or top grade detergent powder with high quality are produced, the last section is to packing.

Technology Characteristics

- No waste water discharge.

- Save energy and reduce consumption, emissions reach the standard.

- Fine powder can be recycled, water can be recycled and the precipitated slurry after collecting can be used for proportioning.

- Environmental friendly.

- Low investment.

Automated Powder Detergent Production

This spray tower machine integrates cutting-edge automatic technology and PLC control, enabling streamlined and uninterrupted powder detergent production. The computerized system offers high accuracy, reducing operational errors and labor requirements. Its design is ideal for businesses seeking increased efficiency, consistent product quality, and scalability. The process is safe and energy-efficient, meeting the needs of diverse detergent manufacturers.

Industry-Leading Design from China

As a product from China, this machine benefits from advanced engineering and reliable manufacturing standards. It supports users globally, including dealers, distributors, service providers, and wholesalers. The robust build, combined with a comprehensive one-year warranty, ensures longevity and peace of mind for customers investing in quality detergent production equipment.

FAQs of Spray Tower Detergent Powder Making Machine:

Q: How does the spray tower detergent powder making machine operate automatically?

A: The machine uses PLC control and a computerized system to automate feeding, spraying, drying, and packaging processes, minimizing manual intervention and increasing overall efficiency.Q: What type of detergent powder can be produced using this plant?

A: This machine is designed specifically for manufacturing cleaner-type detergent powder, offering consistency and high performance for cleaning applications.Q: When is the optimal time for maintenance of the detergent powder making machine?

A: Regular maintenance can be scheduled during non-production hours. The machine comes with guidance for routine checks and a one-year warranty covering essential repairs.Q: Where can this spray tower machine be installed?

A: It can be installed in commercial production facilities, manufacturing plants, or industrial zones, depending on local infrastructure compatibility and space requirements.Q: What is the process involved in producing detergent powder with this machine?

A: The process includes automated dosing of raw materials, spraying them in the tower for drying, followed by cooling and packaging, all managed by PLC control to ensure product uniformity.Q: How is the machine beneficial for distributors and wholesalers?

A: The machines high output and automatic operation allow distributors and wholesalers to reliably supply large quantities of detergent powder, meeting market demand efficiently.Q: What is the usage scope of the detergent produced by this machine?

A: The detergent produced is suitable for household, commercial, and industrial cleaning, offering a versatile solution for a wide range of cleaning needs.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email