|

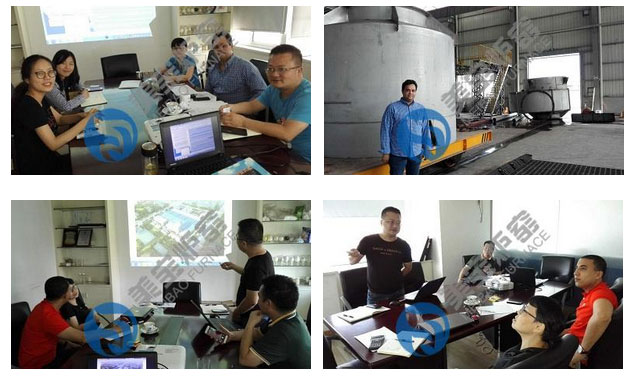

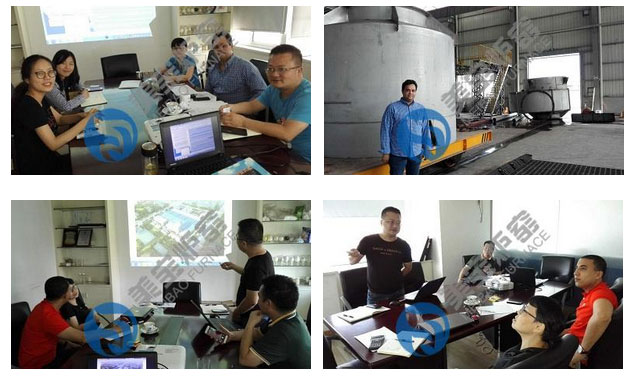

Rubber drying hot air furnace successfully completed debugging 2017-6-6 Our company developed and designed the rubber drying hot air furnace, and successfully completed the commissioning in May in Vietnam, and deliver to normal operation.Compared with the former drying equipment, the hot air furnace has the advantages of convenient operation and maintenance, and obvious energy consumption reduction. The hot air furnace has been used in rubber drying production line in many countries and regions in Southeast Asia  Pakistan customer visit our company 2017-4-28 April 24th,2017,our Pakistan customer came to our office for business inspection(seven from different department),after friendly communication,we signed an important contract.

10TPH detergent powder production line successfully completed installed 2017-5-2 The 10 TPH detergent powder production line designed and supplied by our company was finished installation at April,2017 successfully,and finished commissioning work at May.

Two set of new type detergent powder production line finished According to the needs of the domestic market, the development of the 2 sets of new washing powder after the smooth distribution of the user. The production line is characterized by less investment, easy installation and operation, suitable for small domestic and foreign users.

We adopted the "high-tech enterprise" identified audit 2016-12-2 Our company passed "high and new tech enterprises" identification audit again

The invention patent of biomass hot air furnace In June 18, 2016 received the State Intellectual Property Office Invention patent for our company "Direct biomass fuel hot air furnace including high-temperature purification device" Patent licensing Our company applied for "Direct environmental protection biomass hot air furnace" "hot air furnace for monoammonium phosphate" "Hot air furnace for polymerization aluminium" "anti coking hot air furnace" "indirect biomass hot air furnace" distillers' grains fired biomass hot air furnace" 11 patent in 2015, have been authorized by the State Intellectual Property Office in March 2016.

Heating system for Kunming Liby Daily Chemical company successfully delivered 2015-11-25 Our company provide high efficiency energy-saving hot-air furnace for waste heat boiler for the Kunming Guangzhou Liby enterprise Daily Chemical Industrial Co. Ltd. production base which can produce:80 thousand tons cleanser essence30 thousand tons laundry detergent, have pass the delivery acceptance of design company, construction control unit, owner organization in November,16,2015, start normal production operation. The heating system is widely used in the production of dry heat, the production of steam heat, and the tail gas desulfurization and dust removal, is very high efficiency,environmental saving and energy saving. The system is also the use of our own patented technology, NICE Group,Sinolight are all using this system, Its energy saving effect is obvious.

Company personnel to participate in domestic and international exhibitions AugustSeptemberNovember According to the needs of the market, the organization actively participated in a number of domestic and international exhibitions

South America and other customers to visit the company 2017-8-29 August 19-28, The South American and African countries customers come to our company .The customer investigated the production site of the company, Conduct friendly and detailed communication with related personnel on design, quality control, document management, etc. Satisfied with our work flow, technical research and development, quality control, document traceability and so on

2017 (Sixteenth) China International Chemical exhibition held successfully in Shanghai 2017 (Sixteenth) China International Chemical exhibition held successfully in Shanghai, Our company has participated in this exhibition, and has carried on the exhibition and the propaganda to the company product

Passed the annual surveillance audit of quality system August 19-28, The South American and African countries customers come to our company .The customer investigated the production site of the company, Conduct friendly and detailed communication with related personnel on design, quality control, document management, etc. Satisfied with our work flow, technical research and development, quality control, document traceability and so on

Rock wool production line delivered and start run In June, the rock wool production line at Xinjiang, Jilin and so on, was successfully completed and delivered on time by Meibao. At present, Meibao is doing the design, manufacture and construction work of Anhui, Jiangsu ,Hunan, Chongqing etc for rock wool production line, and will finish the project as agreed.

Complete set of detergent powder production line design contract signed After we friendly communicate with Vietnam Duc Giang Chemicals and Detergent Powder Joint Stock Company (DGC), The two sides signed a contract of detergent powder production line design in June,2017. Meibao will make the general layout design of new factory, project design and construction design of detergent powder production line based on the requirement of Duc Giang.

|

|

Call Me Free

Call Me Free