- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Storage Tanks

- Industrial Conveyor

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Biomass Fired Hot Air Furnace

- Coal Fired Hot Air Generator Furnace

- Coal Burning Hot Air Generator

- Pellet Hot Air Furnace

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Butterfly Valves

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

Liquid Solid Sodium Silicate Production Line

150000 USD ($)/Set

Product Details:

- Type Silicate Production Line

- Material Stainless Steel & Mild Steel

- Capacity 20 - 100 TPD

- Detergent Type Cleaner

- Computerized Yes

- Automatic Grade Automatic

- Control System PLC Controlled

- Click to view more

X

Liquid Solid Sodium Silicate Production Line Price And Quantity

- 150000 USD ($)/Set

- 1 Set

- Automatic bulk discharge

- 3 - 8 persons per shift

- Gas or Electric Furnace

- Detergent, Adhesive, Construction, Water Treatment

- 99%

- Overheat protection, automatic alarms

- Meets international emission standards

- Wet process and furnace process

- 1400C

- Integrated water cooling

- Sodium carbonate and silica sand

- Manufactures both liquid and solid sodium silicate

Liquid Solid Sodium Silicate Production Line Product Specifications

- 28000 kg

- Grey & Silver

- Silicate Production Line

- PLC Controlled

- Stainless Steel & Mild Steel

- 29 m x 5 m x 3.3 m

- 380 V

- Sodium Silicate Production Line

- Cleaner

- 65 kW

- Yes

- Automatic

- 20 - 100 TPD

- Automatic bulk discharge

- 3 - 8 persons per shift

- Gas or Electric Furnace

- Detergent, Adhesive, Construction, Water Treatment

- 99%

- Overheat protection, automatic alarms

- Meets international emission standards

- Wet process and furnace process

- 1400C

- Integrated water cooling

- Sodium carbonate and silica sand

- Manufactures both liquid and solid sodium silicate

Liquid Solid Sodium Silicate Production Line Trade Information

- 2 Set Per Month

- 90 Days

Product Description

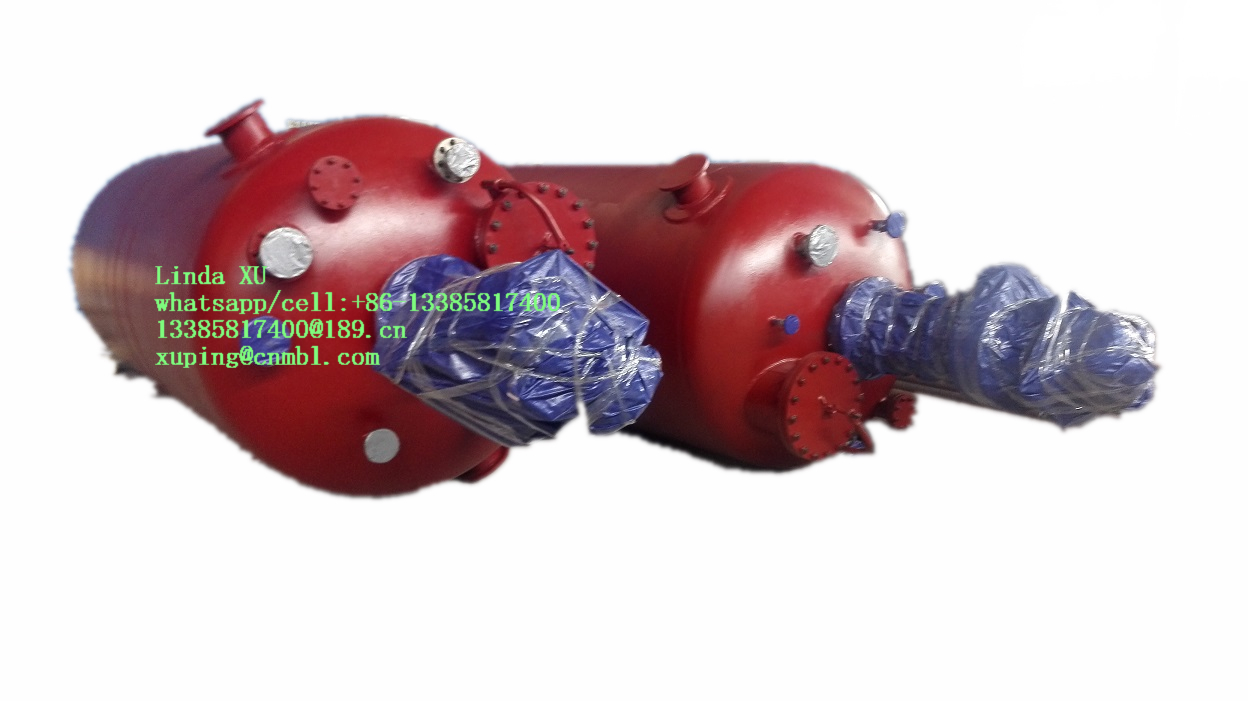

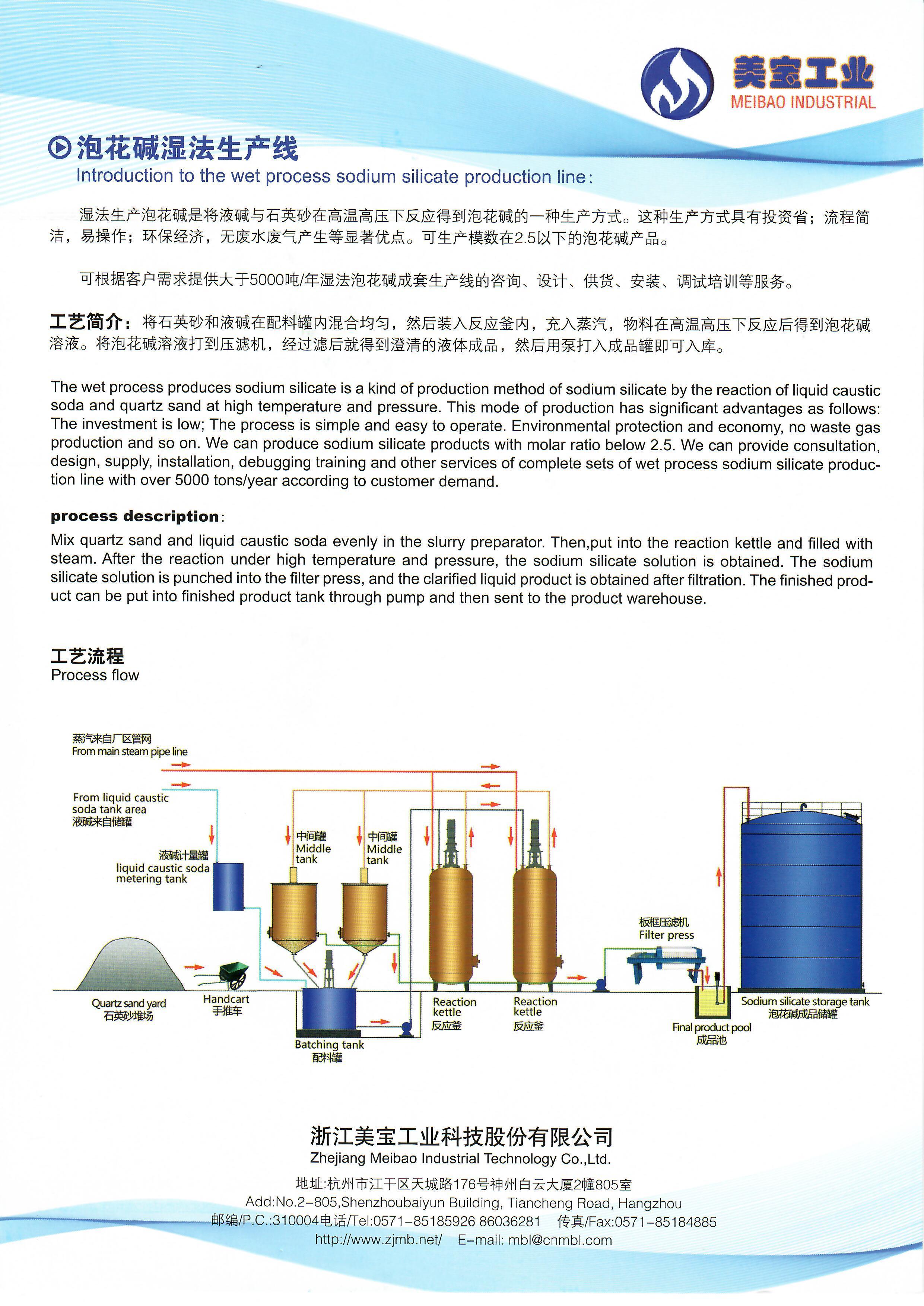

We have created most recent Liquid Solid Sodium Silicate Production Line for sodium silicate manufacturing. There are two procedures for sodium silicate manufacturing. The first is a fluid stage; the second one is a strong stage. Sodium silicate is generally utilized in development material, every day synthetic and different enterprises. It has an effective process response in a fluid stage. Water, quartz sand, and caustic soda are blended in blending tank then the blend is encouraged into a reactor, where steam is presented. The reactant is fluid sodium silicate with its module lower than 3. The sodium silicate created by this Liquid Solid Sodium Silicate Production Line has the modules relying upon prerequisites of various applications. This machine is to be generally utilized in paste making, liquefying mold throwing, quick dry bond and so forth field.

We can supply complete sets of consulting, designing, supply, installing, commissioning and other services on wet sodium silicate production line. This production line is employed for producing low modulus sodium silicate which is below 2.5. Caustic soda and quartz sand are basic raw materials, Ingredients, reaction, sedimentation, filtration are four parts of the entire process. The main equipment in the production line are the reaction kettle, proportioning tank, the filter, tundish, finished product tank, etc.

Technology characteristics of Sodium Silicate Production Line :

- Semi-automatic or automatic production

- Well organized process line, excellent production efficiency, and consistent quality.

- Logical, energy saving layout and clean and tidy factory.

- Key equipment in the production line run steadily and are wear resistant and preservative; that substantially increases the lifespan. The advantages of this production line is because of the years of improvement and optimization.

- This production line is designed to meet the national environmental protection requirements.

Dual Process Flexibility

The system integrates both wet and furnace processes, enabling seamless production of liquid and solid sodium silicate. Operators can select the optimal method depending on specific batch requirements. Automated controls and bulk discharge enhance productivity while maintaining exceptional quality standards.

Designed for Safety and Efficiency

Operator safety is addressed through overheat protection and automatic alarm systems that monitor critical processes. The integrated water cooling and robust construction ensure continuous, stable operation at temperatures up to 1400C, minimizing risks and downtime for high-volume production.

Intelligent Automation and Quality Control

This production line features a state-of-the-art PLC-controlled system, offering precise manipulation of temperature, raw material flow, and discharge protocols. Automated grading and computerized diagnostics contribute to superior product purity and consistent output, meeting industrial demands efficiently.

FAQs of Liquid Solid Sodium Silicate Production Line:

Q: How does the production line maintain product purity above 99% during operation?

A: The system utilizes advanced PLC controls and automated grading mechanisms to monitor and adjust critical parameters throughout both wet and furnace production processes, ensuring that product purity consistently meets or exceeds 99%.Q: What are the main steps involved in producing sodium silicate using this production line?

A: Production involves blending sodium carbonate and silica sand under controlled heating via gas or electric furnaces, followed by cooling in an integrated water system. The output is then automatically discharged in bulk as either liquid or solid sodium silicate.Q: When is it optimal to use the wet process versus the furnace process within the production line?

A: The choice depends on required silicate specifications and production volumes; the wet process generally suits lower temperature and liquid outputs, while the furnace process is ideal for solid silicate and higher temperature requirements up to 1400C.Q: Where can the sodium silicate produced by this line be utilized?

A: The resulting sodium silicate is applicable in diverse industries including detergent manufacturing, adhesives, construction materials, and water treatment, serving as a versatile chemical component.Q: What are the major usage benefits offered by this production line to industrial operators?

A: Benefits include automated bulk discharge, high capacity, efficient energy usage, reduced manual labor, and premium product purity. Safety features and environmental compliance further enhance operational reliability and community acceptance.Q: How does the integrated cooling system improve the production process?

A: The integrated water cooling system stabilizes operating temperatures, enabling consistent production cycles and protecting equipment from thermal stress, which translates to enhanced product quality and extended machinery lifespan.Q: What safety and environmental compliance features does the production line provide?

A: Comprehensive overheat protection, automatic alarm systems, and adherence to international emission standards safeguard both operators and the environment, ensuring safe, responsible and sustainable production.Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free