- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Storage Tanks

- Industrial Conveyor

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Biomass Fired Hot Air Furnace

- Coal Fired Hot Air Generator Furnace

- Coal Burning Hot Air Generator

- Pellet Hot Air Furnace

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Butterfly Valves

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

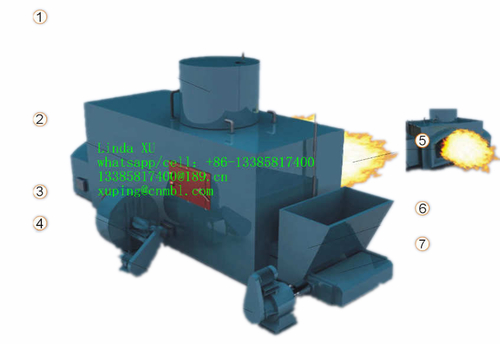

Gas Fired Hot Air Generator

50000.00 USD ($)/Set

Product Details:

- Product Type Gas Fired Hot Air Generator

- Starting Type Electric Start

- Phase Three Phase

- Click to view more

X

Gas Fired Hot Air Generator Price And Quantity

- 1 Set

- 50000.00 USD ($)/Set

Gas Fired Hot Air Generator Product Specifications

- Gas Fired Hot Air Generator

- Three Phase

- Electric Start

Gas Fired Hot Air Generator Trade Information

- Shanghai

- 100 Set Per Month

- 30-90 Days

- Contact us for information regarding our sample policy

- Container Loading

- All India

- ISO9001

Product Description

Due to our quality centric approach, we are indulged in manufacturing, exporting and supplying fine range of Gas Fired Hot Air Generator. This generator is manufactured using quality assured components and innovative techniques under our experts' supervision. The offered generator is extensively demanded in cement, fertilizer, chemical and other industries. For its high performance and robust construction, this generator is highly appreciated among clients. Also, we are providing this Gas Fired Hot Air Generator at viable prices to our esteemed clients.

Features:

- High temperature resistance

- Easy operation

- Reliable construction

- Less maintenance

Further Details:

- The offered equipment is capable of providing fresh and pure hot air

- Exceptional functional efficiency

- Requires minimal charge for its operation

- Easy to conserve its original working condition

- Has extensive applications

- Available in 600KW-20MW working capacity range

- Temperature range of produced hot air is between 100-1000deg.C

A completely automatic multi pass counter present Hot Air Generator contain stainless steel shell kind essential burning chamber housed in several M.S. shell. The frigid air is introduced by an appropriate volume blower fan in first pass, engrosses heat after flue gas way and hence both hot flue gas and chilly air travel in contradictory way in the way which eventually transmissions 90% heat to cold air and brings hot air from hot air opening hole. The organization purposes fully involuntary on temperature detecting device connected at hot air vent that ON-OFF the burner at advanced set temperature. The scheme is a package kind unit, installed on common base frame.

Special Features:

- Clean & adulteration free hot air is obtainable for application

- High thermal competence of approximately 90% on NCV of fuel for subsidiary type

- Substantial cost savings are probable when related with electrical air heating

- Big furnace capacity for whole combustion

- Furnace with high glowing heating surface keeping harmless furnace wall temperatures considerably below the permissible limits.

- High heat transfer area giving longer heater life

- Robust & dependable workings with the least upkeep for fans & controls

- Powder covered, well-lit switch panel with methodical wiring plan with tag nos. etc. for convenient trouble shooting and also better life in manufacturing environment

- Prompt & consistent after sale services along with attitude

RADIATIVE HEAT EXCHANGER:

Radiative Heat Exchanger includes of a series of S.S. Pipes, fused with a able floating Box Header, that rested on rollers, reinforced on a channel frame.

CONVECTIVE HEAT EXCHANGER:

Convective Heat Exchanger includes of a row of S.S./M.S Pipes, fused along with a free fluctuating Box Header refreshed on rollers, maintained on a channel edge. These heat exchangers are available in two stages, for cumulative the general system competence.

HEAT RECOVERY UNIT :

It recuperates heat from the flue gases, and in return it temperatures the arriving clean environmental air through cross flow design.

POLLUTION CONTROL EQUIPMENT:

High competence Cyclone is offered for gathering fine ash from flue gases released in the ambient via the stack.

FBC FURNACE WITH WIND BOX:

Coal /Groundnut shell / Lignite fired FBC system includes of a Nozzle plate with involved Air Plenum and a lateral building frame fastened with Nozzle plate. Categorized CI Cast iron nozzles are fixed on top of nozzle plate. Sand drain pouches are offered for elimination of heavy undesirable silica elements from the FBC Furnace.

FUEL FEEDING WITH SCREW CONVEYOR SYSTEM:

Screw conveyors carried by motors provender the fuel incessantly to the furnace via specially planned Fuel feeding Venturi system assisted by the SFD Fan air.

REFRACTORY MATERIAL:

All the typical / specially molded refractory bricks for furnace walls with fittings and containers are offered. The mandatory Insulation bricks, mortar cements are offered by us. (For Heat Exchanger/ Furnace area Refractory function.)

INSTRUMENTATION AND SAFETY INTERLOCKS:The system provided is tremendously simple and appropriate to run. Alarms and safety meshes have been offered

to safeguard precise functioning of the HAG. The subsequent are some of the security inter locks.

- Lest C.A. Fan is switched on, the F.D.Fan / S.F.D.Fan / I.D.Fan Fuel feeders will not function.

- In case of tall hot air temperature visual/ audio alarms are stimulated on the panel.

- If there are high bed temperature visual/ audio alarms are triggered on the board and fuel feeder rapidity is dropped down to minimum.

- If there is low and high condition of hot air duct heaviness visual/ audio alarms are triggered on the panel for obligatory corrections and observations.

- Visual alarms are triggered, in case of problem in invertors.

- Flue gas temperature

- Furnace bed temperature

- Outlet Hot air temperature

- Draft gauges are provided at

- Outlet hot air duct pressure.

- Furnace suction pressure

- Air wind box

CONTROL PANEL:

The panel is based on PLC that is innovative but accessible controls allowing the worker to run the HAG in manual or automatic mode as anticipated. The control panel contains of chief MCCB, inverter drives for feeders and fans with separate MCBs, PID controllers, annunciation module with hooter, representing lamps and one supplementary contact.

Note: We offer products in different specifications. We design these items as per the details provided by the customers. Instead of being trader, we are reckoned as manufacturers of these items. Industrial factories are the customers of our products rather than shopkeepers, wholesale houses and merchants. We also offer necessary technical guidance and required suggestion for our valued customers.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email