- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Coal Fired Hot Air Generator Furnace

- Biomass Fired Hot Air Furnace

- Pellet Hot Air Furnace

- Coal Burning Hot Air Generator

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

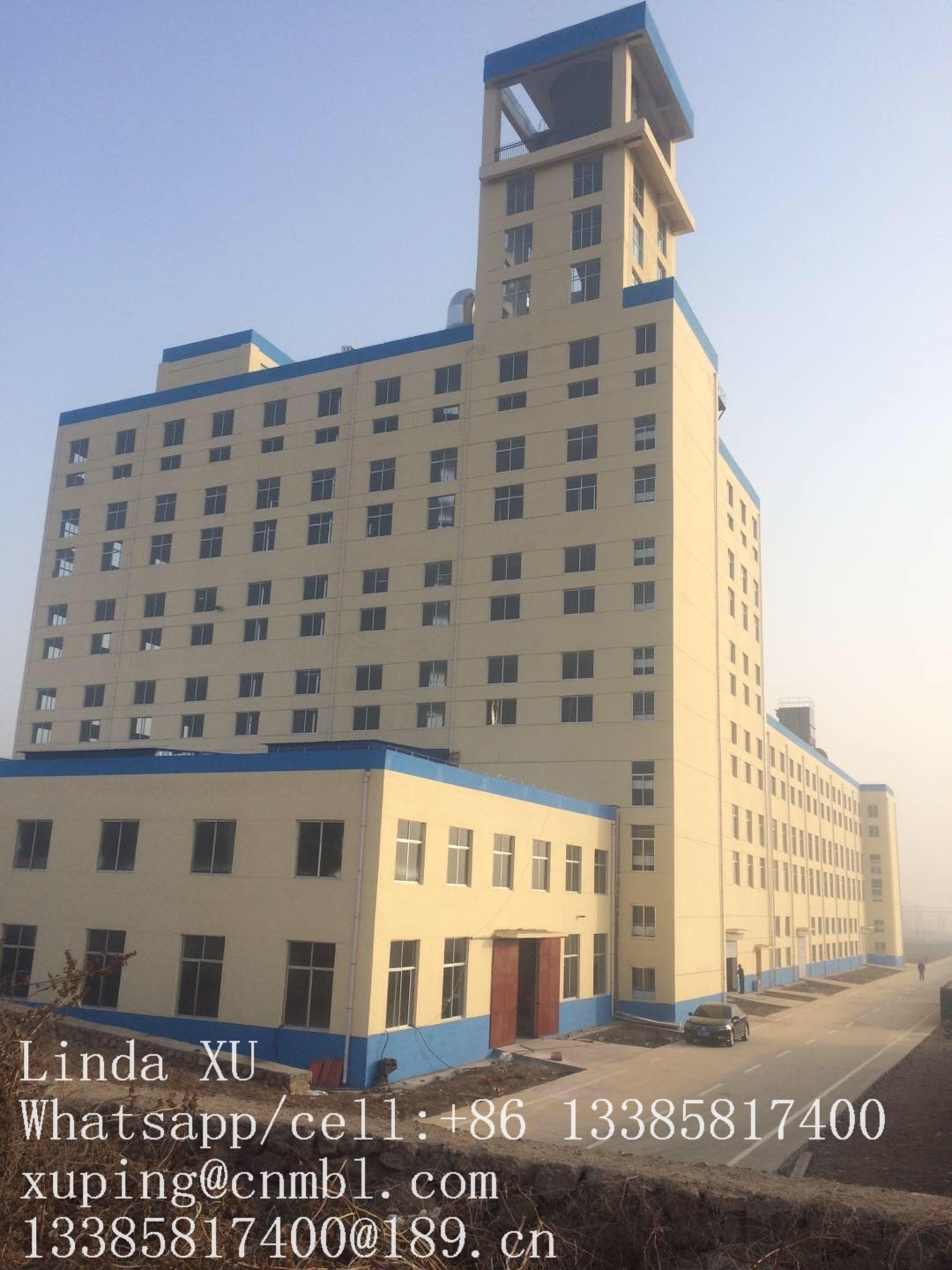

Detergent Powder Plant

100000-500000 USD ($)/Set

Product Details:

- Product Type Detergent Powder Plant

- General Use Chemical industry

- Material Stainless Steel

- Click to view more

X

Detergent Powder Plant Price And Quantity

- 100000-500000 USD ($)/Set

- 1 Set

Detergent Powder Plant Product Specifications

- Detergent Powder Plant

- Stainless Steel

- Chemical industry

Detergent Powder Plant Trade Information

- Shanghai Port

- 100 Set Per Day

- 30-90 Days

- Container Loading

- All India

Product Description

Detergent Powder Plant

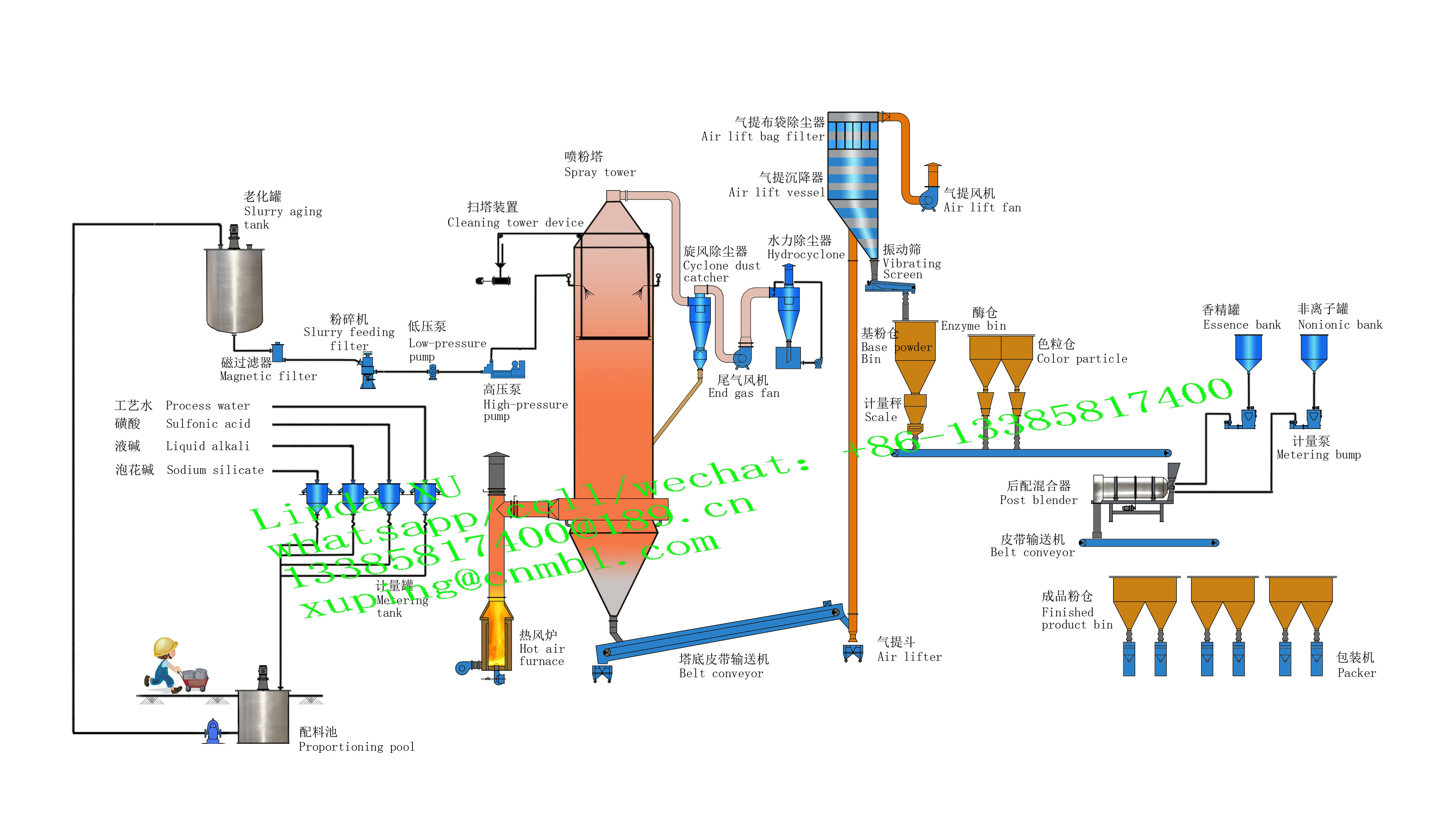

The production gear receives the procedure of tower spray agglomeration method, yearly yield limit 5000 to 250000 tons. Obvious particular gravity of item 0.25 to 0.50 g per cm3

A wide range of powder materials, fluid materials are weighed individually as indicated by the equation, sent to proportioning tank to make slurry, after hydrated maturing, squashing and sifting by maturing framework, sent to top of shower tower by hey weight pump. Structure fog particles through shower spouts, dried by hot air created by hot air heater. At the base of the tower, empty particles of cleanser powder are shaped. At that point via transporting, maturing, base powder is made. In the wake of sieving, different materials, for example, compound, shading particles, embodiment, nonionic and so forth. should be included into base powder, and afterward set up together into the post mixing blender. In the wake of blending and pulverizing, last hello there quality cleanser powder in medium and top evaluation is made, and in the end for pressing.

Technology attributes:

Tailgas after drying is managed by essential deduster and auxiliary hydrodeduster. Spare vitality and meet outflow standard.

Fine powder gathering from dedusting procedure is totally back to tower, enhance yield of base powder.

Workshop environment is given immaculate dedusting framework, guarantee the workshop environment clean.

Control framework can receive easy to use manual operation or central computer incorporated programmed control.

Emissions of waste gas of entire production framework achieve principles, no sewage release.

Further Details:

Detergents are utilized for several purposes, and there are extensive variety of substrates e.g. exterior to be cleared and of soils. We mostly pay attention on chief substrate i.e. textile fabrics.

In detergent powder plant, for engineering of detergents additional than 40 and odd constituents can be utilized. A detergent in detergent factory is a preparation including essential ingredients viz. builders, surface active agents,fillers, boosters,and auxiliaries. Individually these basic substances have its benefits and disadvantages

We not only aid the detergent manufacturing by offering spray dryers disc atomizers or Nozzle but with the team of experienced technocrats and experts, we help our customers by offering technical know how for detergent formulations with backward integration for the important raw material industrial e.g. sulphonation and sulphation by batch procedure. We offer technical expertise to our admired clients bearing in mind:

Obtainability of raw materials

Comfort of manufacturing

Price of Raw materials

Cost of engineering

Appropriateness of finished products

Market trend

We trust in quality,and offer latest logical means for basic resources,intermediates and over goods.

We, being devoted,knowledgeable and specialists deliver our facilities to our customers for detergent industrial all under one roof.

Not only we are content by providing the technical knowledge and detergent industrial plants, we are dedicated to help our customers for up gradation, optimum output, cost reduction, with outstanding outcomes of the detergents. We take distinct care for amalgamation of optical brighteners, perborates, enzymes and perfumes in spray dry detergent powder.

We detect some rules as to excellence regulator of spray dried powder viz:

Decent color properties

Wanted element size and spread

Precise bulk thickness

Precise remaining moisture gratified

Absence of tackiness

Even composition and arrival

For spray drying of detergent powder, the machine varied powder is transformed into slurry of wanted solid fillings. Then following deaeration if obligatory of slurry, it is cleaned to get constant viscidness and this slurry is impelled and sprayed via nozzle. Squirted slurry is desiccated by cocurrent or countercurrent of hot air.

This spray dehydrated powder with suitable cooling is blended with optical brighteners, perborates, perfumes and enzymes. This substance is then packaged in desired packing.

Total processes of detergent powder industrial to stuffing of spray dehydrated powder can be completely semiautomatic, automatic, or manual contingent on the customers requirement.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free