- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Coal Fired Hot Air Generator Furnace

- Biomass Fired Hot Air Furnace

- Pellet Hot Air Furnace

- Coal Burning Hot Air Generator

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

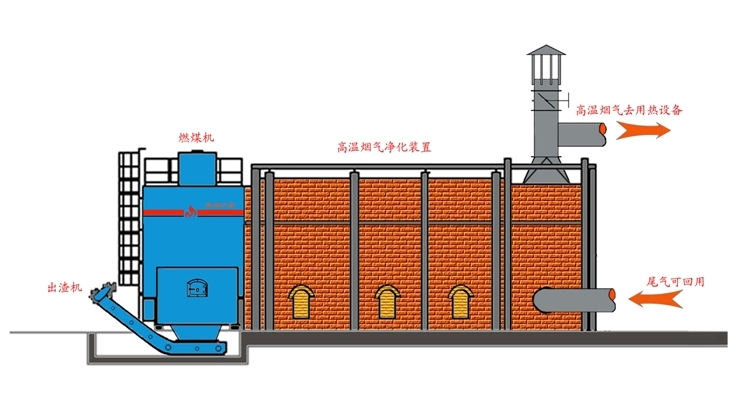

Biomass Fired Furnace with Environmental Way Dry

150000 USD ($)/Set

Product Details:

- Product Type Biomass Fired Furnace with Environmental Way Dry

- Usage Industrial

- Click to view more

X

Biomass Fired Furnace with Environmental Way Dry Price And Quantity

- 150000 USD ($)/Set

- 1 Set

Biomass Fired Furnace with Environmental Way Dry Product Specifications

- Industrial

- Biomass Fired Furnace with Environmental Way Dry

Biomass Fired Furnace with Environmental Way Dry Trade Information

- 10 Set Per Month

- 30-90 Days

Product Description

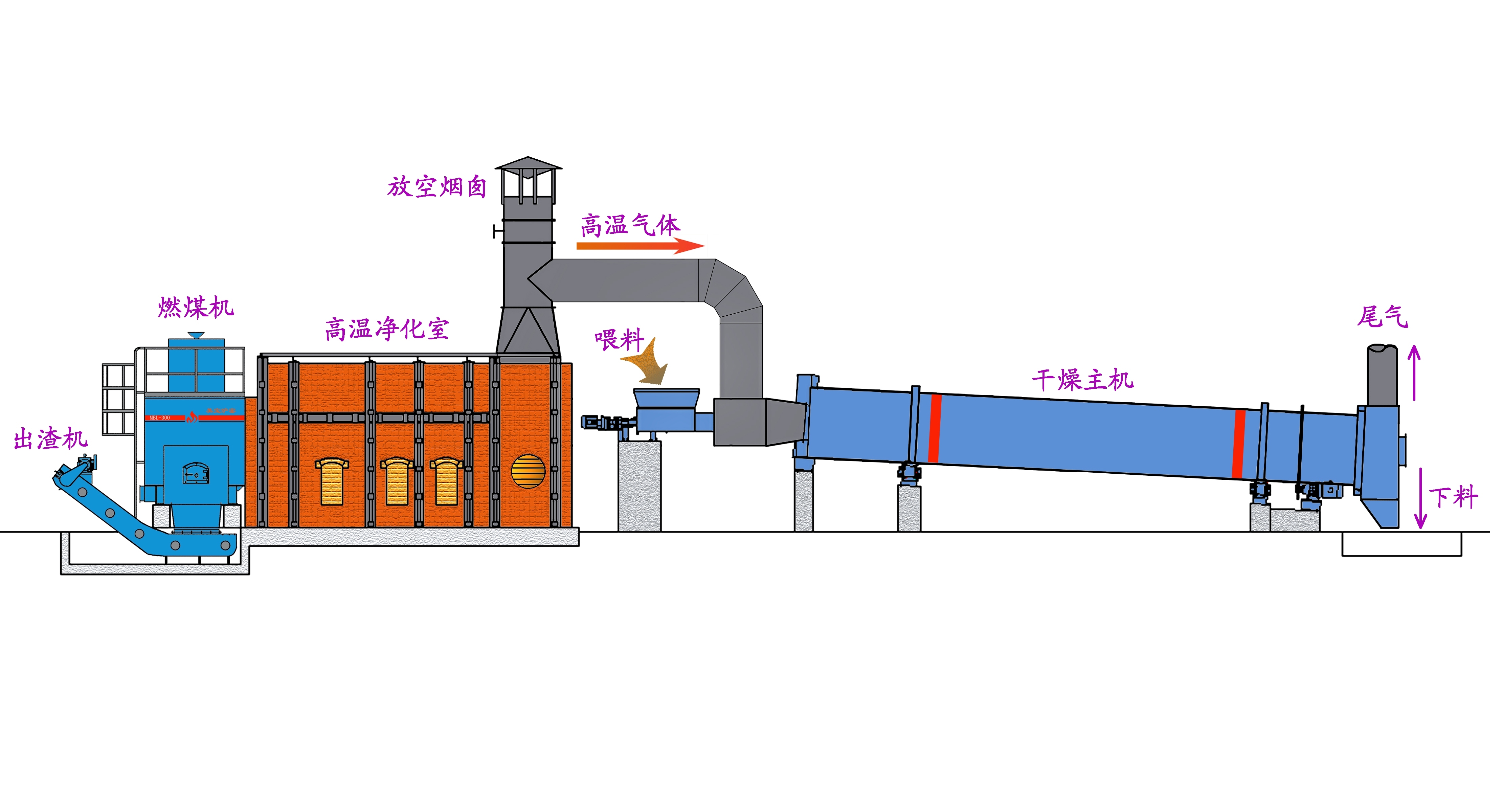

Biomass-Fired furnace with environmental way Drying furnace

Technical characteristics:

It adopts the secondary combustion and purifying equipment for the hot flue gas, makes the temperature of flue gas enter into heat exchanger evenly and stably, prevents the flame from burning heat exchanger locally, which meanwhile reduce the tar content and dust content that enter the heat exchanger, reduce the wastages of heat exchanger and dust accumulation, increase the heat efficiency, and lengthen the life-span.

Heat exchanging system of MBH indirect coal-fired hot air furnace is counter current heat-exchange, flue gas flows outside the pipe, fresh air flows inside, which strengthen the heat exchange.

Heat exchanger contains jet pipe and plug-in pipe, the air whirls in pipe at a high speed, which reduce the heat resistance, lengthen the exchange time, and increase the heat exchanging factor.

There is emergency protecting equipment response to incidents such as sudden power failure.

- Using flue dust purification technology to control the flame burning on the local heat transfer tubes, and reduce the dust content, increase the life of the heat exchanger and thermal efficiency.

- Heat exchanging system of indirect hot air furnace is counter current heat-exchange, flue gas flows outside the pipe, fresh air flows inside, which strengthen the heat exchange.

- Heat exchanger uses advanced jet and the interposer structure to improve the heat transfer efficiency.

- Heat efficiency output of the highest hot air temperature is 600 Hot air temperature fluctuates within

- Long lifespan with low maintenance.

- Simple to operate, easy to maintain. High security, there is no danger of explosion

Application:

Foodstuff, medical products, Chemical, Building materials, etc.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email