- Home Page

- Company Profile

-

Our Products

- Hot Air Furnace

- Chemical Production Line

- Detergent Powder Plant

- Gypsum Drying Production Line

- Industrial Slate Conveyor

- Rotary Filter

- Sodium silicate plant

- Sodium Silicate Production Line

- Detergent Powder Plant Washing Powder Making Machine

- Industrial Detergent Powder Production Line

- Batch Feeder

- plunger pump

- Detergent Powder Line

- Cyclone Separator Dust Collector

- Slurry Mill

- Liquid and Powder Detergent Plant

- Liquid Sodium Silicate Plant

- Soda Ash For Detergent Powder Plant

- Liquid Sodium Silicate Plant Water Glass Making Machine

- Sodium Silicate Solid

- Detergent Powder Production Line

- Polymeric Aluminum Drying Production Line PAC

- Calcium Hydrogen Phosphate Drying Production Line

- Washing Powder Production Line

- Rotary Blender for Detergent Powder Plant

- Sodium Silicate Manufacturing Equipment Solid Sodium Silicate Drying Furnace

- Hydrocyclone Separator

- Detergent Powder Making Plant

- Spray Drying Tower

- Rotary Kiln Drying Production Line

- Washing Liquid Production Line

- Liquid Detergent Production Line

- Chemical Process Equipment

- Bag Filter

- Post Blending Mixer

- Quartz Sand Drying Production Line

- Aging Pot

- High Pressure Pump

- Detergent Spray Tower

- Sanitary Angle Type Filter

- Washing Powder Machine Crusher

- Liquid Detergent Making Machine

- Calcium Chloride Production Line

- Sodium Silicate Plant

- Stainless Steel Heat Exchanger

- Detergent Powder Packing Machine

- Mixing Vessel

- Desulfurization And Denigration System

- Pulse Airflow Dryer

- Spray Dryer

- Flash Dryer

- Detergent Making Machine

- Washing Powder Making Processing Line

- Ecofriendly Detergent Powder Production Line

- Cosmetic manufacturing production line Ginger washing line

- Washing Powder Making Machine

- sodium Silicate line Detergent manufacturing line Washing powder line

- Liquid Solid Sodium Silicate Production Line

- Solid Sodium Silicate Plant

- Washing Powder Plant Detergent Powder Making Machine

- Spray Tower Detergent Powder Making Machine

- Liquid Detergent Making Machine

- Rotary Mixer

- New Detergent Powder Manufacturing Line

- Turnkey Solution for Detergent Powder Production Line

- Industrial chemical Dosing Tank with agitator for detergent production line

- Liquid Detergent Making Machine

- Hand Sanitizer Production Line

- Detergent Powder Manufacturing Plant

- Washing powder line premixing system Main equipment

- Washing Powder Soap Production Line Machine

- Washing line for powder detergent Washing powder

- Industrial Sodium Silicate Plant

- Liquid detergent making machine

- Washing powder plant

- Solid and Liquid Water Glass Making Plant

- Detergent Powder Manufacturing Plant

- Hot Air Generator

- Pressure Vessel

- Drying Equipment

- Heating Equipment

- Biomass Fired Furnace with Environmental Way Dry

- Chain Grate Burner

- Coal Fired Hot Air Furnace Equipment

- Coal Fired Hot Air Generator

- Heat Exchanger

- Coal Fired Hot Air Generator Furnace

- Biomass Fired Hot Air Furnace

- Pellet Hot Air Furnace

- Coal Burning Hot Air Generator

- Biomass Fired Hot Air Furnace with Safe and efficiency

- Biomass Hot Air Generator

- Coal-Fired Hot Air Generator

- Vibrating Screen

- Boiler Auxiliaries

- Dedust Equipment

- Industrial Chemical

- Contact Us

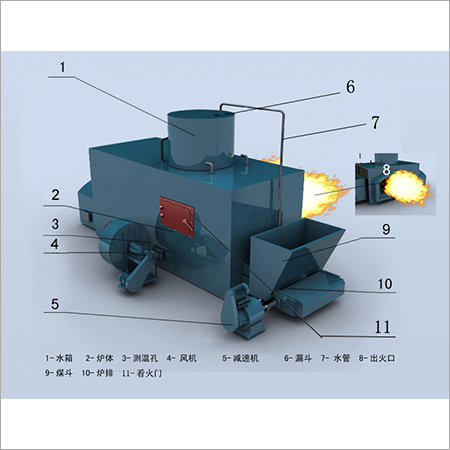

Pellet Burner

20000.00 - 200000.00 USD ($)/Set

Product Details:

- Product Type Pellet Burner

- Condition New

- Type Pellet Burner

- Click to view more

X

Pellet Burner Price And Quantity

- 20000.00 - 200000.00 USD ($)/Set

- 1 Set

Pellet Burner Product Specifications

- Pellet Burner

- Pellet Burner

- New

Pellet Burner Trade Information

- 10 Set Per Month

- 60-90 Days

- Contact us for information regarding our sample policy

- All India

Product Description

We have cornered the entire market by providing superior grade assortment of Pellet Burner in 600KW to 20 MW capacity range to the clients. This burner is manufactured using the best in quality components under the prudent observation of adroit professionals at our advanced production unit. Strictly examined on predefined industry standards, this burner is known for generating hot air with uniform intensity. In addition, this Pellet Burner (Pellet Furnace) can be purchased from us at market leading prices.

Key points:

- Robust construction

- Free from defects

- High performance

- Simple to install

Pellet Burner Briquette Burner

- Generated hot air is free from pollutant

- Exceptional performance

- Helps to save more fuel cost when compared to gas or oil operated burner

- Simple maintenance technique

- Extensive applications

- Available in 600KW-20MW capacity range

- The temperature range of produced hot air is between 100 to 1000 degree C

Further Details:

Pellet burners can be erected on several boilers in the marketplace. The burner is offered with a greater regulator that grips security, monitoring, and controls the ignition. The burner is ignited employing a hot air element while boiler temperature is below the predetermined thermostat set. Adaptable hysteresis of the thermostat through the regulator for the best configuration. The touch screen too shows many valuable properties like pellet consumption, statistics, average power, operating times and even the regular temperature of the water.

The initial process is automatic in numerous steps to get an efficient and rapid start-up. 120 seconds following the burner thermostat is also called to heat the burner is kindled and burns usually. The demonstration on the regulator can also demonstrate what effect the burner is functioning at. The burner has 5 power stages and is convenient to connect and to regulate for gas. Dusting of the ash is automatic as the burner is delivered with an air scrubbing compressor.

The ATMOS A25 pellet burner is envisioned only for excellent quality pellets deprived of bark with 6 8 mm width, 16 - 19 MJ.kg-1 caloric control (white pellets) and 5 - 25 mm length. The benefit of this burner is programmed ignitron pellets by explosion spiral which ardors up the pellet whenever is desirable. The burner and boiler function for extreme output with competence 85 - 90 % and with the finest excellence of burning. Unlike the viable goods which cannot mechanically ignite and they first keep a hot layer that reasons operation for lesser output with a little waste gas temperature underneath 100 C. Such operation makes compression of acids and tar in the burning chimney and chamber, higher consumption, lower effectivity, lower superiority of burning, progressive emissions and more often scrubbing. By our products, we dirt the ash from the reservoir in 7 - 30 days dependent on kind of fuel and yield of the boiler. The burners are not appropriate to burn dark pellets that can do clinkering. In such case, it is required to clean the scorching chamber in period of 1 - 3 days and you misplace the ease of such heating.

In the case of, that you need to burn lower excellence wood pellets prepare burner pneumatic cleaning.

The burner is preferably measured dependent on ideals of the buffer tank's two instruments (TV and TS). The switch unit examines completely automatically boiler of the buffer tank and safeguards the heating system continuously has adequate energy available.

The burner's electronic switch unit also panels the boiler circuit pump, boiler's flue gas fan, and/or the solar system.

The burner's electronic unit does it possible to regulate the burners process liable on four instruments in such way, that while the solar panel device notices it is decent to heat the buffer tank via energy added from solar collector, the burner's parameter safeguards the tank is only frenzied by means of pellets up to the equal of a sensor TK (TS2) that is located amid sensors TS and TV in the tank.

The burner works as given: When the burner obtains a knack to start or there ascends a necessity to twitch heating, the conveyor fodders pellets hooked on the nozzle of the burner and the eruption spiral illuminates the pellets up. When the pellets are sweltering adequately strong, the burner twitches working at a set output, which it retains up until the organization is heated. Following it the burner is switched off and the bits in the burner chamber are burnt down. The whole cycle is continuously repeated if wanted. Production of the boiler and other resolutions of the burner are controlled by the burner electronic instruction, that makes it imaginable to control procedure of the boiler to real conditions of the entire system.

Producing very less ash content, this Pellet Burner is known to provide uniform heat while carrying out various metallurgical operations. This burner is manufactured using quality approved components under the strict guidance of adept team members as per predefined industry standards. This Pellet Burner is available with us in multitude of specifications at affordable market rates within committed time frame.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Call Me Free

Call Me Free